The best way to enhance your business is to adapt your workday to flexible manufacturing—an innovative process using a computer to simplify production processes.

Here are your reasons to invest in flexible manufacturing.

Save More Money

The central goal across manufacturing companies is to save money. Your best avenue is to invest where you see potential, whether that entails serving fewer shipping routes upon production or renting smaller spaces to save on leasing.

Manufacturers spend most of their time on the production line, so it makes sense to save there. The best way to save money is to invest in technology to simplify the production process across the entire warehouse. By pursuing flexible manufacturing, workers save time on creation and assembly.

Improve Quality Control

The benefits of investing in flexible manufacturing do not end with saving money; it goes on with better quality control. Utilizing flexible manufacturing at various factory locations enhances all quality control.

Your specialists have better methods to check for design inconsistencies, such as color matching. The great thing about this process is quality control can send the product back for reworking before producing it.

Produce Less Waste in Production Lines

An essential part of manufacturing is producing less waste—reducing excess is difficult, but it isn’t impossible.

By using flexible manufacturing, workers have preplanned outlines of a product’s appearance, including customizable product options for customers looking for specifics.

Enhance Traditional Production Practices

Adapting to changes is necessary, especially if it impacts traditional production practices. An assembly line may include workers who need access to tools that might not be available.

Create better access to tools with flexible manufacturing; it improves mobility around the work area and reduces time spent on each project.

Find Fewer Errors in the Final Product

Errors are bound to happen in systems like flexible manufacturing. Fortunately, the errors aren’t permanent and won’t hold production back for long. Flexible manufacturing simplifies production by guiding workers with blueprints. If something goes wrong, it’s easy to send the design back for inspections and fixes.

Another great thing about flexible manufacturing is workers don’t have to follow a particular sequence. At any phase of production, workers can send a product back if they believe it has issues. You can send it back during quality control checkpoints or at the starting point—there is no limit or set order to follow.

Increase Productivity Throughout the Factory

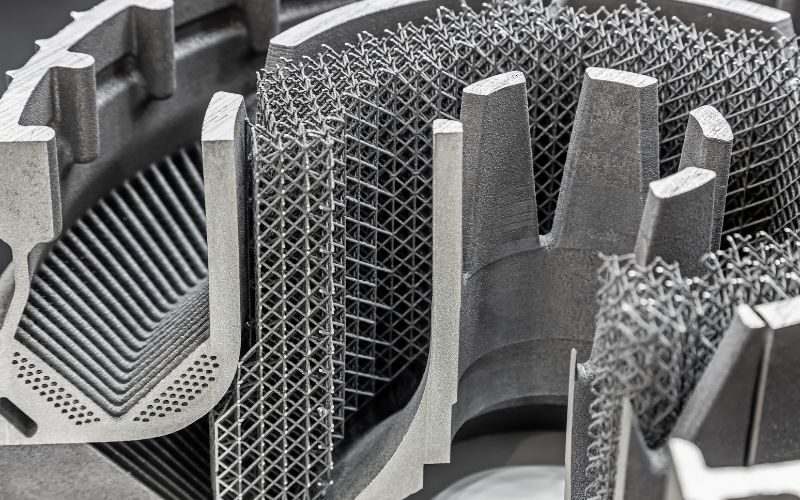

In this field, 3D printing impacts flexible manufacturing the most. 3D printing has changed the manufacturing industry by improving productivity. Manufacturing companies can produce more products with fewer workers and factories, and workers can print from anywhere, including small shops.

It’s essential to adapt manufacturing routines and best practices. If adaptability is all you ask for in the manufacturing industry, then flexible manufacturing is for you. Improve your business by adopting modern capabilities.

Image Credit: part of the housing of the first engine support made on a 3D printer printed by OlegDoroshin Image License: 512545798

end of post … please share it!

-------------------------------------------------------------------------------------------------------------

-------------------------------------------------------------------------------------------------------------

home remodeling reference (links to internal page)

|

|

|

|

| directory | photos | forms | guide |

Helpful article? Leave us a quick comment below.

And please share this article within your social networks.